From Crisis to Control

The client, a prominent mining company in Australia, had embarked on a critical infrastructure management initiative to assess the condition of their extensive water pipeline network. Historically, the client’s approach to maintaining their ageing water pipelines involved systematic and routine excavations and replacements, based primarily on the water pipelines’ age. This traditional method, while straightforward, proved to be inefficient and extremely costly, leading to unnecessary replacements and disruptions.

Recognising the need for a more precise and cost-effective strategy, the client has adopted a pipeline condition assessment program, aiming to optimise their replacement and rehabilitation efforts.

The introduction of a condition assessment program is a significant advancement for the client, promising to yield substantial financial savings—estimated in the tens of millions of dollars annually. By utilising modern diagnostic tools and techniques, the company can now target specific sections of the pipeline that require attention, rather than indiscriminately replacing entire segments based solely on their age.

This targeted approach not only reduces costs but also minimises operational disruptions and extends the service life of the existing pipeline infrastructure.

This case study focuses on the comprehensive assessment conducted on the Trunk Main Pipeline, facilitated by Detection Services on behalf of the client. The assessment employed the p-CAT™ testing methodology to evaluate the pipeline’s condition. The primary objectives of the field tests included identifying blockages, air pockets, and areas with wall thickness deterioration, providing a detailed understanding of the pipeline’s integrity and performance.

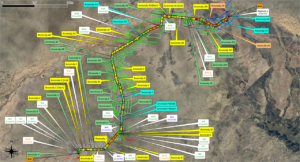

The Trunk Main Pipeline, constructed mainly in 1972 using asbestos cement (DN300 and DN250), with a relocated section in 1982 made of ductile iron cement lined (DICL) pipes, spans approximately 47.9 kilometres. The pipeline is divided into two key segments:

Segment 1: Covering 27.7 kilometres, this segment starts at River Pump Station A at River B, extending southwards around Mine site C, crossing city D, and ending at the discharge Storage Dam E, just upstream of Booster Pump Station 01.

Segment 2: Spanning 20.2 kilometres, this segment begins at Booster Pump Station 01 of Storage Dam E, continuing southward and concluding at Mine F.

The condition assessment utilised GIS maps and technical manuals provided by the client, adhering to standards AS1711-1975 for asbestos cement pipelines and AS-NZ 2280-1999/2004 for DICL pipelines. Key assumptions included specific outside diameters and wall thickness measurements for both AC and DICL pipeline sections.

Once the reporting and analysis phase was finalised, the findings from the p-CAT™ testing were presented, offering insights into the current state of the Trunk Main Pipeline and providing actionable data to inform the client’s maintenance and rehabilitation strategies.

The Outcome

The total equivalent wall thicknesses determined by p-CAT™ considers the following mode of pipeline deterioration for asbestos cement pipes:

- Loss of effective wall, the loss of the structural integrity of the pipeline wall. This mode of deterioration differs from the first two as it causes the pipeline to weaken in strength without significant reduction in wall thickness. In asbestos cement the calcium is leached from the asbestos cement, leaving behind a weakened cement matrix. p-CAT™ is able to determine the effective wall thicknesses along the length of the analysed pipeline, which is a representation of the AC pipe wall strength.

The following pipeline wall condition was identified during the p-CAT™ analysis:

Segment 1:

- 3% of the total pipeline length has a remaining wall thickness of between 63% and 69%. These sections are considered the highest priority on Segment 1.

- 9% of the total pipeline length has a remaining wall thickness of between 70% and 79%.

- The rest of the pipeline (62.7% of the total length) has remaining wall thicknesses of between 80% and 88%.

Segment 2:

- 1% of the total pipeline length has a remaining wall thickness of between 51% and 69%. These sections are considered the highest priority on Segment 2.

- 3% of the total pipeline length has a remaining wall thickness of between 70% and 80%.

- The rest of the pipeline (54.3% of the total length) has remaining wall thicknesses of between 81% and 86%.

The following known features and anomalies, and their resulting recommended actions were also identified during the signal analysis:

Segment 1:

Three HIGH priority anomalies representing:

- Three air pockets at AV05A, AV09A and AV12A.

Eight medium priority anomalies representing:

- Three potential small air pockets or deteriorated sections;

- Three possible deteriorated sections or replacement sections;

- Two potential unrecorded fittings or deteriorated section.

Six low priority anomalies representing:

- A closed check valve at Pump Station 01;

- A material change from AC to DICL;

- Presence of SV06A, and IV09;

- A concrete encasement or soil compaction at railway crossing;

- Discharge to turkey-nest tank at the end of the section of interest.

Segment 2:

Five HIGH priority anomalies representing:

- Two potential unrecorded replacement sections of a low wave speed material, or possible entrained/entrapped air section, or deterioration.

- A possible entrained/entrapped air at AV06B, or possible an unrecorded replacement section, or potential deterioration.

- A possible entrained/entrapped air, or possible deterioration.

- A possible unknown offtake or branch with air, or a potential replacement section of a low wave speed material, or possible short, deteriorated section.

Four medium priority anomalies representing:

- An unknown offtake, or possible deterioration, or a potential small air pocket.

- One possible unrecorded replacement, or deteriorated section, or potential air pocket.

- Two possible deteriorated sections or small air pockets or potential replacements.

The total equivalent wall thicknesses determined by p-CAT™ considers the following modes of pipeline deterioration for DICL pipes:

- Internal corrosion, where the structural integrity of the cement lining is reduced through debonding;

- External corrosion, where the structural integrity and the bond of the cement lining is intact.

During analysis, p-CAT™ found four potential unrecorded replacement sections of a low wave speed material seen as anomalies with specific instructions provided as to their location eg. Anomaly 2F, 27 m located 297 m north of AV07B

These p-CAT™ potential unrecorded replacements of a low wave speed material can also be interpreted as deterioration, entrained/entrapped air, or off-takes.

As mentioned, the client’s approach to maintaining their aging water pipelines involved systematic and routine excavations and replacements, based primarily on the pipelines’ age. It was apparent there was a need for a more precise and cost-effective strategy, resulting in the adoption of a condition assessment program.

Condition assessment programs are crucial in preventing major incidents and bursts in water pipelines, which can lead to significant operational and financial consequences. This case study illustrates how a prominent Australian mining company transitioned from a traditional, costly, and inefficient maintenance approach to a precise condition assessment program.

By leveraging modern diagnostic tools and techniques, the company has been able to target specific sections of their pipeline that require attention. This targeted approach has not only reduced costs by tens of millions of dollars annually but also minimised operational disruptions and extended the service life of their infrastructure.

If you would like to learn more about our pipeline condition assessment solutions, please get in touch with us here.